1.2311 Tool Steel Tool Steel Specification and Information

1.2311/ P20 Hot Rolled Steel Plate Plastic Mould Tool Steel China Die Steel and Tool Steel

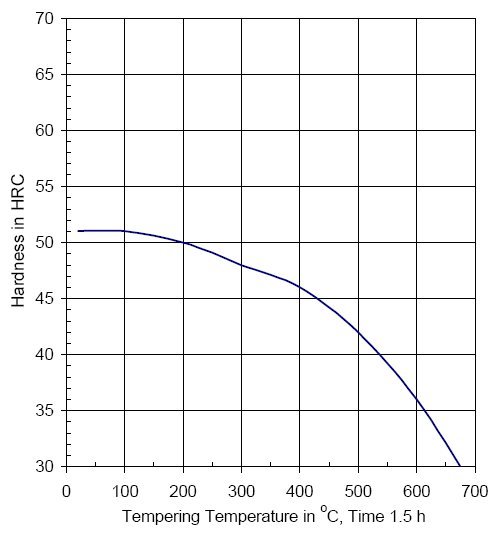

Before nitriding, stress-relief annealing is recommended at 580 °C. (Meusburger standard) After the hard chroming the mold must be annealed about 3 to 4 hours at 180 °C to avoid brittle fractures from hydrogen. Slow heating to tempering temperature immediately after hardening. Minimum time in furnace: 1 hour per 25 mm part thickness.

O1 Tool Steel DIN 1.2510 100MnCrW4 SKS3 Otai Special Steel

1.2312 Tool Steel Data Sheet - West Yorkshire Steel Co Ltd Author: Microsoft Office User Keywords: 1.2312 is high tensile alloy tool steel supplied in the hardened and tempered condition. With its higher sulphur content it offers better machineability than 1.2311 plastic mould tool steel grade. Created Date: 10/9/2022 5:32:59 PM

P20 /1.2311 Tool Steel Plate For Plastic Mould Sawing To Size Black Surface

Description. Germany DIN 1.2311 Cold working alloy tool steel and 1.2311 Mechanical Properties, Chemical Element, Cross Reference, Datasheet. Datasheet for: Steel Grades:Tool Steel And Hard Alloy: 1.2311. Category.

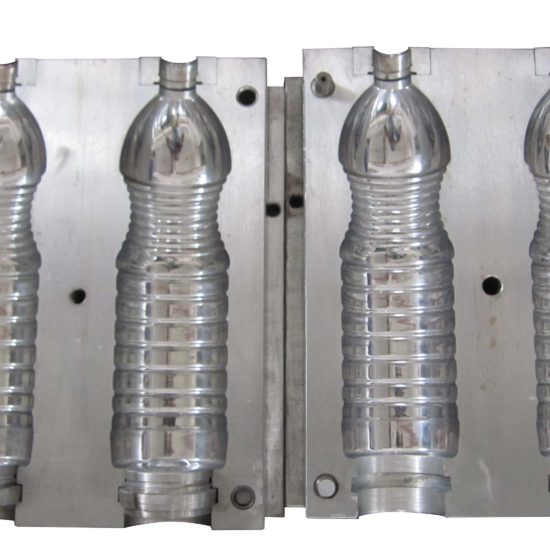

1.2311 /P20 plastic mould steel

1.2312 tool steel suppliers and stockholders delivering to the whole of the UK.. With its higher sulphur content it offers better machineability than 1.2311 plastic mould tool steel grade. Form of Supply. West Yorkshire Steel are stockholders and suppliers of round bar, flat bar, plate and block. Rectangular pieces can be sawn from flat bar.

1.2311 P20 Special Die Steel Alloy Tool Steel China JIS S45c and GB 45

1.2311 (P20) Low temperature tempered plastic mould tool steel (P20) Product features. X 40 CrMnMo 7; As supplied condition: Tempered to a hardness of 280 to 325 HB (950 - 1100 N / mm2) Tempered plastic mould steel, easy to polish, nitridable, chrome-plated, uniform hardness over the cross-section up to a thickness of approx. 405 mm.

1.2311 Steel Plate P20 3Cr2Mo Plastic Tool Steel Special steel china supplierOTAI Special

® Industeel Trademark - W 1.2311 - 09/2019 3 MACHINING W1.2311 grade performs very well in drilling and in milling using high speed steel or carbide tools. Cutting conditions (cutting speed, feet rate, etc.) depend on the tool, but W1.2311 is a well known grade for which any tool maker can provide cutting conditions adapted to its tools.

P20 (1.2311) Tool Steel SUPREME STEEL

DIN 1.2311 Tool Steel is a low alloyed steel with 2.0% Cr ,0.15%Mo as per DIN standard.As plastic mold tool steel, it has good toughness,wear resistance after Nitriding. It is mostly used in the hardened and tempered condition with hardness 285-320 HBW.Typical application for this steel are:For large injection and compression molds, Blow molds.

AISI P20 / 1.2311/ 3CR2MO Plastic Mold Tool Steel Flat Bar Length 2200mm

P20 tool steel differs from area to area in the different countries.Europeans generally use the DIN spec-DIN EN ISO 4957 standard materials (1.2311 and 1.2312), while in Japan steel industry standard, PX5 is the new standard P20. And the Americas Countries, Grade steel P20 is the most and wide used steel grade material.

XT215CR12 Tool Steel Suppliers, Manufacturers, Exporters From India FastenersWEB

1.2311 and 1.2312 are plastic mould tool steels, suitable to operate in high temperature, used mainly for plastic moulds, hydroforming tools and frames for plastic pressure dies. They are highly hardenable, resistant to tempering and strong in high temperature. 1.2311 enables better texturing and polishability compared to 1.2312, making an A-2.

P20 Plastic Mould Steel DIN 1.2311 Tool Steel Ventura Steels

The tempering pre-hard state, hardness is 285 ~ 325 HBS. Beginning temperature of 1050 ℃, the end in 850 ℃, with the temperature forging furnace slow cold. Annealing temperature of 710 ~ 740 ℃, and the furnace slow cold, hardness HB 235 or less. Quenching temperature of 840 ~ 870 ℃, oil cooling or 180 ~ 220 ℃, quenching salt bath.

Diving into 1.2311 Tool Steel Sheet Dimensions

1.2312 Tool Steel 1.2312 tool steel suppliers and stockholders delivering to the whole of the UK. West Yorkshire Steel are stockholders and. With its higher sulphur content it offers better machineability than 1.2311 plastic mould tool steel grade. Analysis Carbon 0.35-0.45% Chromium 1.80-2.00% Manganese 1.40-1.60% Molybdenum 0.15-0.25%

1.2311 Equivalent Suppliers Factory Distributor Wholesale Price SOLAR

steel should be tempered for about 4 hours at 180ºC (356ºF) to avoid any hydrogen embrittlement. This method of machining can be used on W 1.2311 grade. Precaution should be take to avoid the presence, after machining, of a rehardened surface layer ("white layer"). This layer should be completely removed by grinding and polishing.

P20/1.2311 Steel

Grade Brief: DIN 2311 is an alloy tool steel with good machining ability even when hardened and tempered (Brinell 300). This steel has a polished surface and is one of the most regularly used requirements for machine cut plastic molds and casting dies. DIN 2311 is frequently hardened and tempered, ready for machining.

1.2379 Tool Steel D2 SKD11 Cr12Mo1V1 Alloy Steel

West Yorkshire Steel are stockholders and suppliers of round bar, flat bar, plate and block. As an alloy tool steel grade 1.2311 is commonly supplied in the hardened and tempered condition with a supply hardness of approximately 300HB. This steel gives an excellent polished finish and is one of the most widely accepted specifications for.

1.2311 Tool Steel Tool Steel Specification and Information

1.2311 Tool steel is a German Die steel, the steel by "super clean" production process, pre hardened, showing the height of micro pure and excellent homogeneous structure, excellent polishing and light etching engraving. After heat treatment, processing and polishing performance is good, can be carried out, and can be processed, suitable.

P20 Plastic Mould Steel DIN 1.2311 Tool Steel Ventura Steels

1.2311 is a pre hardened high tensile tool steel which offers ready machineability in the hardened and tempered condition, therefore does not always require further heat treatment. This eliminates the risks, cost, and waiting time of heat treatment and avoids the associated possibility of distortion or even cracking.